Description

Features and Benefits

Multi Stage Booster Pumps

Some of the most durable booster pumps available. The floating impeller design minimizes thrust loads allowing for continuous operation without damage to motor bearings, mechanical seal, or pump hydraulic components.

![]()

High Flow TFC Low Pressure Membranes

Additional element types & ratings available.![]()

Pump Mounting System

The Booster Pump mounts to a separate bracket and slides onto the frame making field repairs and service easy.

![]()

300 psi FRP Membrane Housings

Gloss 300 psi Fiberglass Reinforced Plastic (FRP) Membrane Housings are standard, Stainless; Stainless Steel also available.

![]()

Key Features

- High flow 5 micron front mounted prefilter for ease of service

- Pump throttle valve & pipe mounted discharge pressure gauge

- Permeate & Concentrate flow meters

- Integrated recycle valve

- Quick connect fittings on gauges & recycle operation for ease of service

- Stainless braided hoses for protection against corrosion, leaks, & fraying

- Glycerin filled gauges for accurate & steady pressure readings

- Float switch and pretreatment interlocks - standard on all systems

- Panel mounted concentrate pressure gauge

- Low pressure mechanical switch w/time delay snubber valve

- High quality gloss 300 psi FRP housings - stainless housings available

- Replaceable schedule 80 pvc fittings for ease of field repairs

- True union couplings on inlet & outlet of motor. No plumbing disassembly required for change out

Additional Resources

OPTIONAL EQUIPMENT

Digital Display Electronic Control Box - The RO Control Box controls all the functions of the RO system. It also incorporates a TDS monitor as well as feed water temperature. It also controls the timing sequences of the solenoids and low-pressure switch, which are impossible to control mechanically. In addition, it gives a time delay for motor start and controls the float switches. It also controls higher functions such as the fast flush or permeate flush when ordered with the system. The Control Box has four different switchable programs installed. Custom controller programming is available to each customer’s preference and custom graphics.

Digital Display Electronic Control Box - The RO Control Box controls all the functions of the RO system. It also incorporates a TDS monitor as well as feed water temperature. It also controls the timing sequences of the solenoids and low-pressure switch, which are impossible to control mechanically. In addition, it gives a time delay for motor start and controls the float switches. It also controls higher functions such as the fast flush or permeate flush when ordered with the system. The Control Box has four different switchable programs installed. Custom controller programming is available to each customer’s preference and custom graphics.

Chip Control Box - The Chip Control Box is an economical option for a RO controller available for both eh SIMPLX and NRO - 440 systems up to 4 membranes. The smaller modular design allows for easier assembly, service, and flexibility with a clean and logical layout. It features 6 LED lights to indicate the system operation of the RO unit. The controller removes the need for a low-pressure switch to control the pump and a start delay to prevent system cycling. A switching power supply operates on 96-264VAC, automatically adjusting to the operating voltage. The voltage at the supply terminals is the voltage for the pump and valves.

Chip Control Box - The Chip Control Box is an economical option for a RO controller available for both eh SIMPLX and NRO - 440 systems up to 4 membranes. The smaller modular design allows for easier assembly, service, and flexibility with a clean and logical layout. It features 6 LED lights to indicate the system operation of the RO unit. The controller removes the need for a low-pressure switch to control the pump and a start delay to prevent system cycling. A switching power supply operates on 96-264VAC, automatically adjusting to the operating voltage. The voltage at the supply terminals is the voltage for the pump and valves.

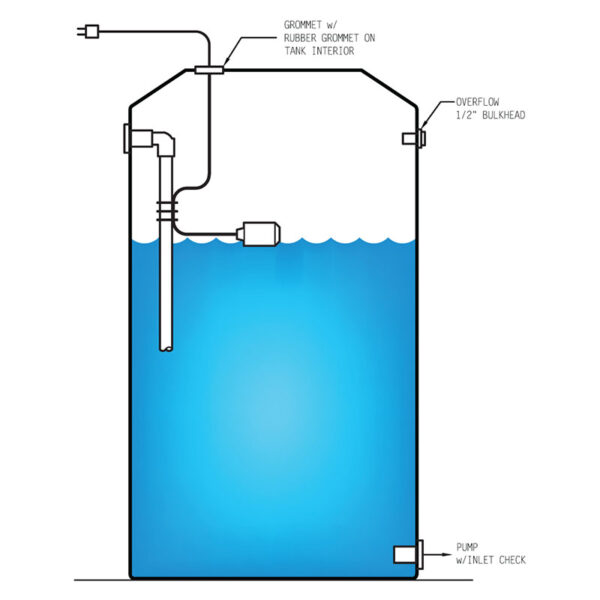

Repressurization Systems - Pre-plumbed and ready to use when you receive them. These systems are custom-built to your specific application. Included in the plumbing package; 1" inlet threaded bulkhead fitting, float switch with 20ft cord, ½" overflow threaded bulkhead fitting w/plug, and 1" bulkhead fitting at the bottom of tank w/1" foot valve. All plumbing is pre-installed in your choice of storage tank size.

Repressurization Systems - Pre-plumbed and ready to use when you receive them. These systems are custom-built to your specific application. Included in the plumbing package; 1" inlet threaded bulkhead fitting, float switch with 20ft cord, ½" overflow threaded bulkhead fitting w/plug, and 1" bulkhead fitting at the bottom of tank w/1" foot valve. All plumbing is pre-installed in your choice of storage tank size.

Additional system gauges - Additional panel mounted pressure gauges for additional system monitoring.

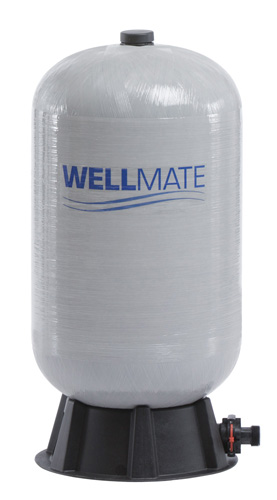

Bladder Tank Control - Used to charge a pressurized bladder tank instead of atmospheric storage. Used when smaller quantities of RO water are needed. Storage is restricted by pressure tank size. All controls and components are included to pressurize the bladder tank, including check valve and pressure switch.

Bladder Tank Control - Used to charge a pressurized bladder tank instead of atmospheric storage. Used when smaller quantities of RO water are needed. Storage is restricted by pressure tank size. All controls and components are included to pressurize the bladder tank, including check valve and pressure switch.

Permeate Flush - Uses the RO permeate water for flushing foulants from the system. Soaking the RO elements during standby with permeate can help dissolve scale and loosen precipitates, reducing the frequency of chemical cleaning.

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

* 110 Volt Not Available ** Minimum pressure of 35psi dynamic

*** The stated product performance is based on data taken after 30 minutes of operation at the following test conditions: 2,000 mg/L NaCl solution at 225 psig ( 1.5 MPa) applied pressure, 15% recovery, 77o F (25o C), pH 6.5–7.0